Duplex 2205 Stainless Steel Material Properties

Applications include chemical processing oil and gas exploration marine and other high chloride environments and paper digestors.

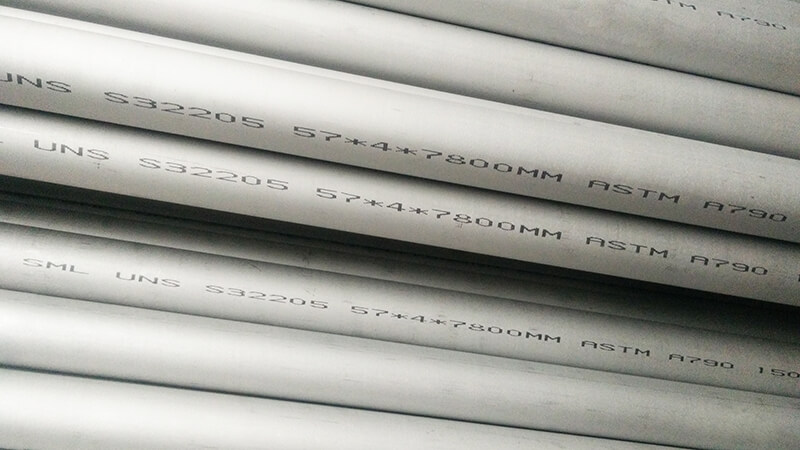

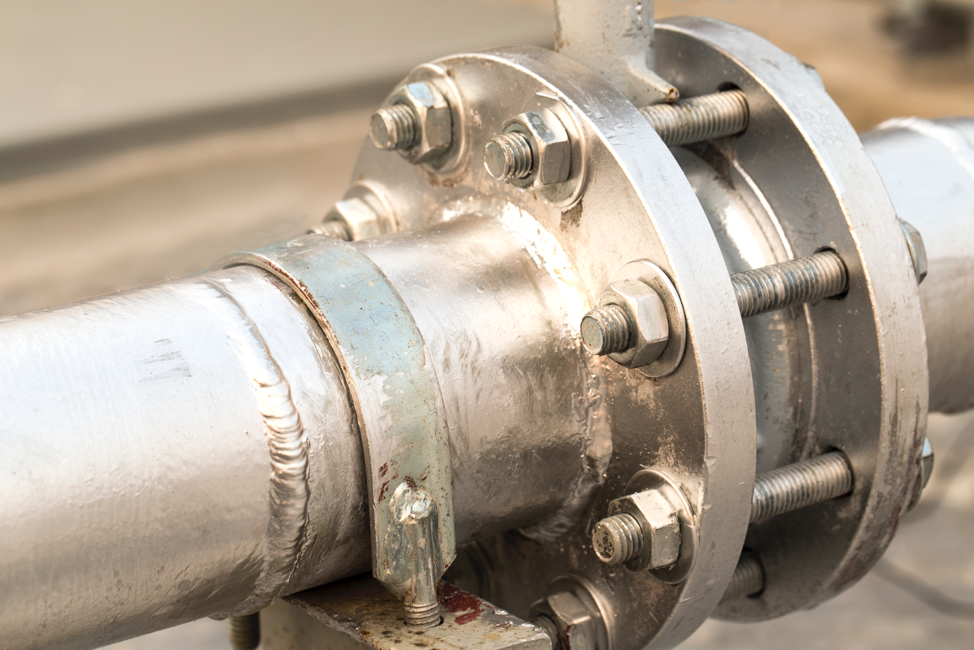

Duplex 2205 stainless steel material properties. Mechanical properties duplex stainless steel 2205 uns s31803 pipes tubes fittings flanges fasteners plates and bar. Their microstructures consist of a mixture of austenite and ferrite phases. As a result duplex stainless steels display properties characteristic of both austenitic and ferritic stainless stee ls. Alloy 2205 material has lower nickel and molybdenum contents than austenitic stainless steel and have.

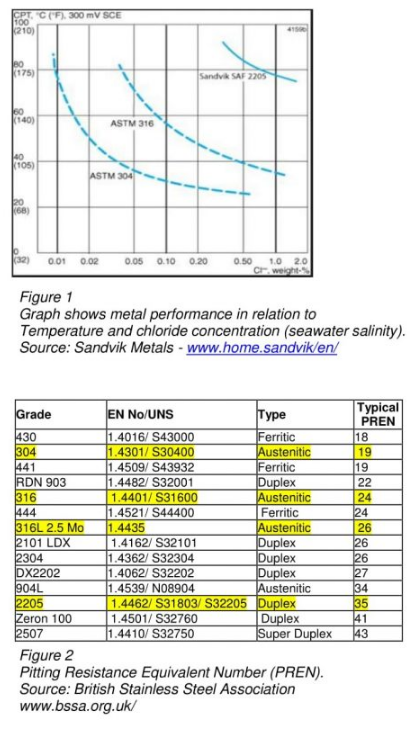

The recommended filler material for 2205 stainless steel is 2209. Its most important properties are excellent corrosion resistance and high strength. 2205 is a two phase ferritic austenitic stainless steel with high strength and excellent corrosion resistance as supplied in the annealed condition with a maximum brinell hardness of 290 rc31 characterised by high yield strength double that of the standard austenitic stainless steel grades good fatigue strength plus excellent resistance to stress corrosion cracking crevice pitting. Saf duplex 2205 stainless steel uns s32205 s31803 alloy material.

2205 is the most widely used duplex ferritic austenitic stainless steel grade. This quality along with long service life and low maintenance requirements led to the use of 2205 duplex stainless steel in pedestrian bridges. Use of duplex grades higher mechanical properties chromium content and duplex microstructure s32304 316l 317 ln 316l 2 5 mo 200 300 s31803 s32205 400 mpa. The microstructure provides resistance to stress corrosion cracking and ensures high strength.

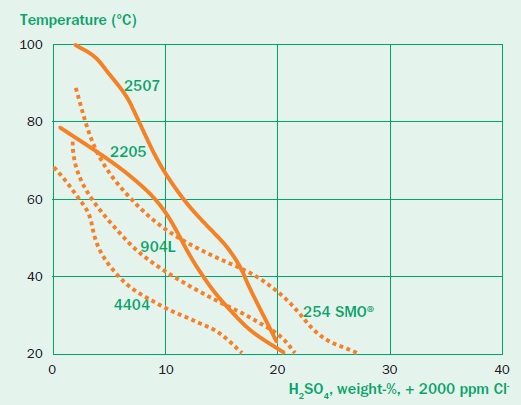

Combining many of the beneficial properties of both ferritic and austenitic steels 2205 is the most widely used duplex stainless steel grade. The helix in marina bay singapore and the harbor drive pedestrian bridge in san diego ca both use 2205 as a primary structural material providing high strength sustainable structures with cutting. Its high chromium and molybdenum content gives the stainless steel excellent corrosion resistance. Duplex steel 2205 butt weld fittings.

Saf derives from sandvik austenite ferrite the nominal chemical composition of saf 2205 is 22 chromium 5 nickel 3 2 molybdenum and other alloying elements such as nitrogen and manganese. Agent exporter dealer distributor stockist stockholder and supplier in india. Materials of construction 2205 255 2507 2304 6mo and clad. Duplex s tainless steel are extremely corrosion resistant work hardenable alloys.

Saf duplex 2205 stainless steel uns s32205 formerly known as uns s31803 and commonly known as alloy 2205 has a mixed microstructure of austenite and ferrite and is a two phase alloy based on the fe cr ni series. The uns designation for saf 2205 is s31803 s32205 and the en steel no. It is the most widely used duplex stainless steel grade and is characterized by high yield strength double that of the standard austenitic stainless steel grades. This combination of properties can mean some compromise when compared with pure austenitic and pure ferritic grades.