A Vacuum Pump Can Remove Moisture From A Hermetically Sealed System Because

A 1 5 mmhg b 2 0 mm hg.

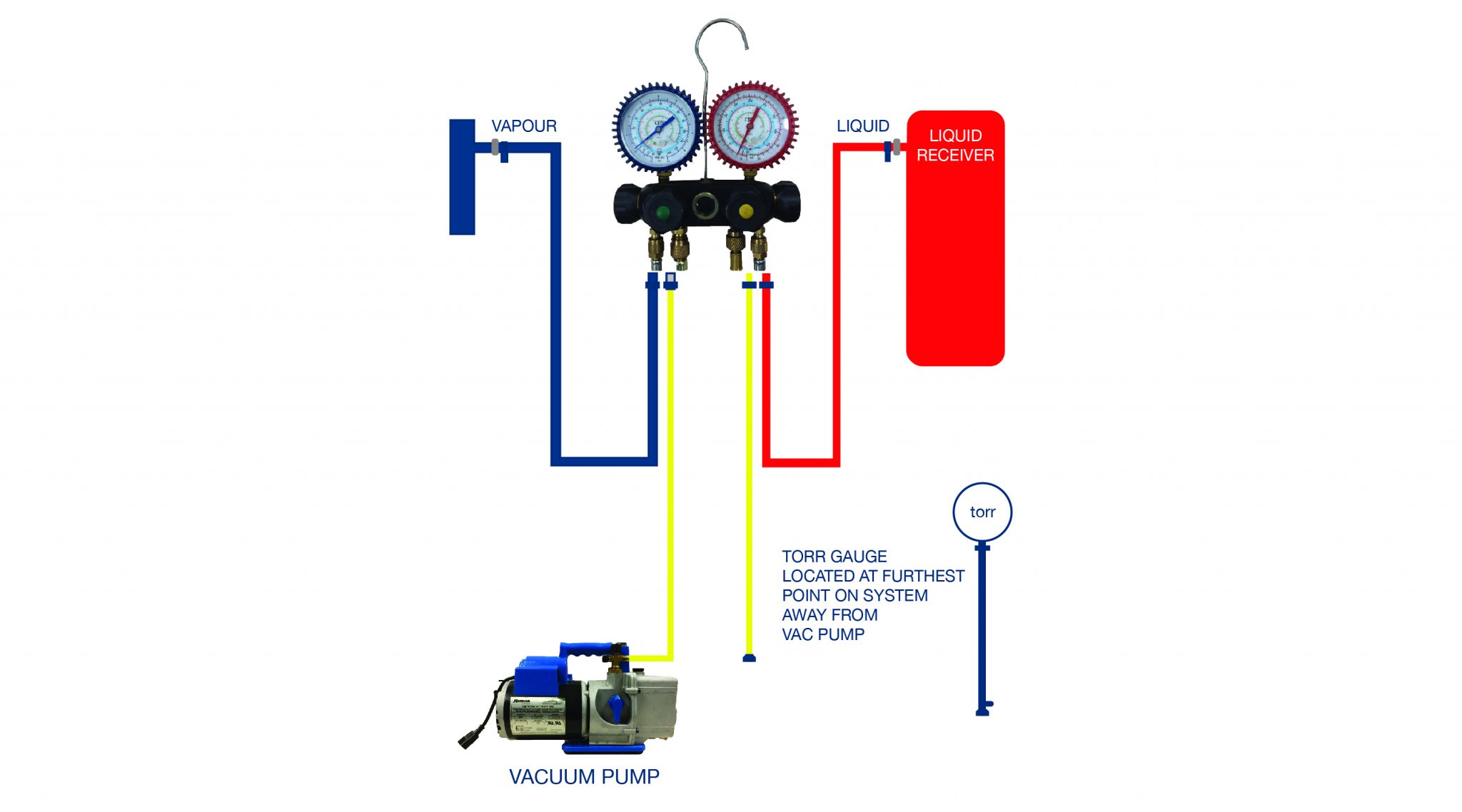

A vacuum pump can remove moisture from a hermetically sealed system because. The meaning of a deep vacuum involves reducing the pressure in the system to about 250 to 500 µm. It typically has a rounded steel outer shell that is permanently welded shut and which seals operating gases inside the system. Getters are especially important in sealed systems such as vacuum tubes including cathode ray tubes crts and vacuum insulated panels which must maintain a vacuum for a long time. If the vacuum rises slowly and stops there is moisture in the system and evacuation should be continued.

If you can hold a 500 micron or lower vacuum then you know you have a clean dry and leak free air conditioning or refrigeration system. Oxygen or compressed air should never be used because they contain moisture and moisture reacts with oil in the system to for acids organic solids r12 r22 r502 r134a will hydrolyze a chemical reaction with water forming hydrochloric and hydrofluoric acids and more water. If the vacuum rises to atmospheric pressure you have a leak that needs to be repaired. A use a dryer b introduces a drying agent.

Q a vacuum pump can remove moisture from a hermetically sealed system because it. After achieving a vacuum the container can be sealed or the vacuum pump can be left running. Recall however that the reason you are using a vacuum pump is that you want to remove the air. Any presence of moisture in the gas being pumped can lead to the pump rusting because of the absence of lube oil.

According to ashrae guideline 3 1996 if the pressure in a system rises from 1 mm hg to a level above during a standing vacuum test the system should be checked for leaks. A vacuum pump can only remove water air and gases in a system. Gas ballast or a purge system introduces air between pump stages to blow condensed vapors through the pump mitigating mechanical wear and tear on the pump of internal condensation. Rotary screw dry pumps are used in applications where a high vacuum is required up to 0 010 mm hg and the process gas is not compatible with lubricating oil in oil sealed rotary pumps.

Building your own system you can have a vacuum approved humidity sensor inside your chamber and then based on its feedback mix dry and humid gas into the chamber. C lowers the presure boils the water and causes it to evaporate.