8018 Welding Rod Amperage

On the other hand a 3 16 inch 7024 rod will have an amperage range of 220 t0 280 amps.

8018 welding rod amperage. However most prefer using them with alternating current ac. Different types of welding rods online. Typically a inch 7024 welding rod will have an amperage range of between 100 t0 160 amps. In general the 7018 rod is used with currents up to 225 amps.

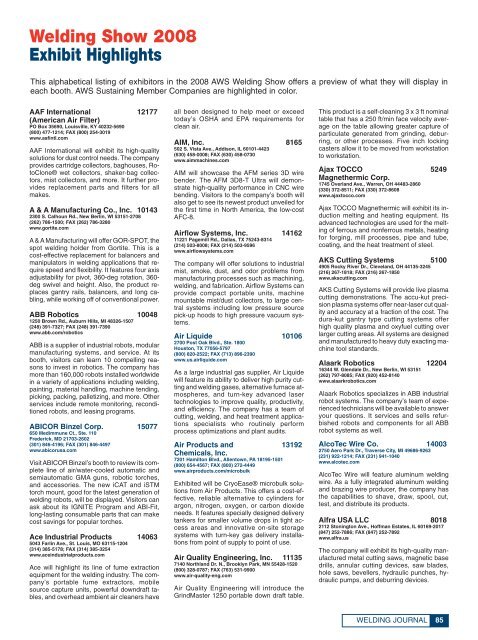

That would mean using 90 amps of current. Read most complete rod guide now. Welding consumables catalog ı 41 stick smaw electrode excalibur 8018 c3 mr welding positions typical applications all except vertical down shipbuilding piping and gas storage tanks weathering steels cross country pipe repair designed to produce a 1 nickel deposit premium arc performance square coating burn off. Amperage deposition rate lbs hr amperage range voltage range 3 32 dcep or ac 100 2 47 70 110 variable 1 8 dcep or ac 135 2 87 90 160 variable 5 32 dcep or ac 170 3 84 130 220 variable 3 16 dcep or ac 250 5 86 200 300 variable note.

Whether you are a novice welder or a seasoned pro this chart is a handy tool to keep close while welding. Different types of welding rods compared. The 7024 welding rod polarity. 7014 s yield strength is 67 700 psi while its elongation is 2 to 29 4 minimum the third number 1 in 7014 indicates that you can use this rod in all four positions the last digit of 4 however signifies the electrode coating and also the type of power supply that you can use for such welding rod.

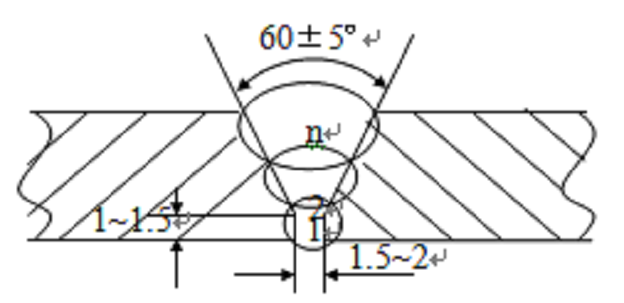

The e7018 is a versatile welding rod frequently used for low and medium carbon steel welding. In turn the rod diameter you use depends on the thickness of the steel you are welding. The 7024 welding rod work with both alternating and direct current. Type of coating weld position and recommended current types.

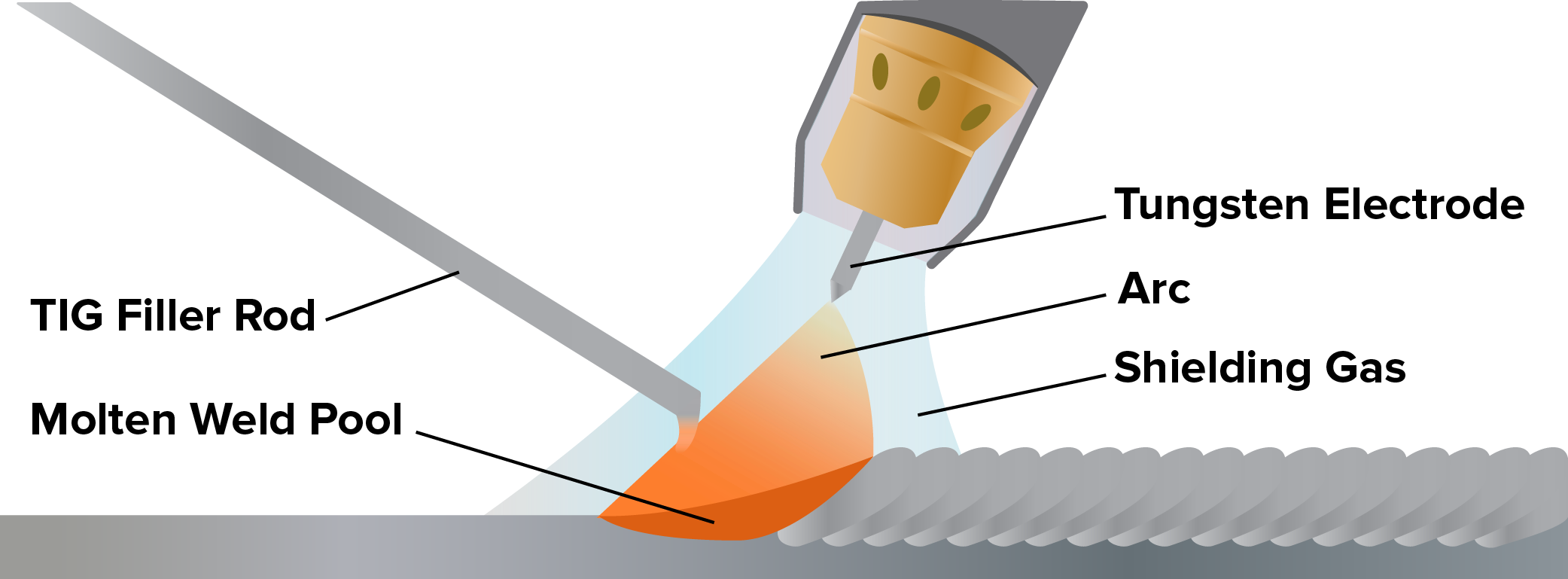

Excalibur 8018 c3 mr from lincoln electric is a 1 nickel all position electrode for fabrication or repair of 1 nickel steels. Also referred to as a low hydrogen rod this electrode has a flux coating with a very low hydrogen content allowing a minimal amount of hydrogen into the weld puddle the molten weld beads are protected from contamination moisture and hydrogen in the atmosphere by the iron containing powder. Excalibur 8018 c3 mr we use cookies to help our website work more effectively and efficiently and to align our services and advertisements to your needs. Optimum conditions are in boldface type.

Here is a detailed stick electrode welding amperage chart. A rule of thumb is to use 30 amps of current per 1 32 inch of rod diameter. Advantages of 6010 6011 6013 7010 7014 7018 and 7024 welding rods. The 70 corresponds to a tensile strength of up to 79 900 pounds per inch psi.

Reviews of the best welding rods online. Before launching into our reviews of the different types of welding rods and electrodes we thought it d be helpful to point out a quirk. The correct welding amperage used with this rod depends on the rod diameter.