4 Satin Finish Stainless Steel

For example one common applied finish is 4 which you will find on your average restaurant or kitchen equipment food processing or dairy equipment and elsewhere.

4 satin finish stainless steel. The easiest of the finishes to maintain no 4 finish is used for work surfaces handrails and where appearance is important. This finish uses between 120 and 320 abrasive grit depending on the application. Satin bracelet in stainless steel. No 4 finish stainless steel is the workhorse of the light fabrication industry.

There are different opinions about the appearance of the satin surface of stainless steel. For some an atlas is equivalent to a shiny finish. For others it means a transparent opaque and milky appearance. 4 satin the industry standard satin finish is similar to 3 except more refined looking and a smoother appearance.

Satin finish is whatever the customer considers satin finish. This easy to clean finish has a typical ra between 0 05 0 1 micrometers. Satin finish stainless steel. The higher the abrasive grit used the finer and more reflective the look.

After initial polishing the final finish is achieved by polishing with 120 180 grit abrasive belt. A no 4 surface is produced by cutting the surface with abrasive belts to remove a very small amount of metal without affecting its thickness. There are differing opinions on what a satin finish looks like on stainless steel. Our 304 stainless steel sheet 4 finish meets the criteria for both the 3 and 4 finish.

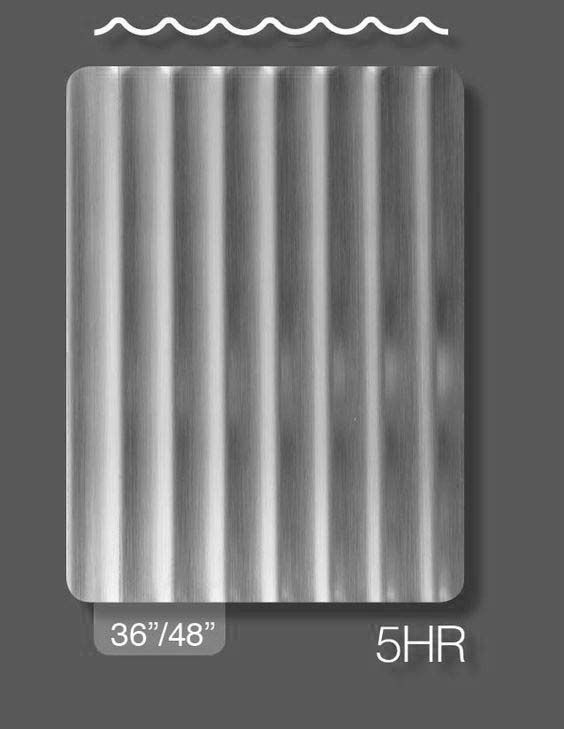

304 stainless steel sheet 4 finish is the brushed finish commonly seen on kitchen appliances and backsplashes. A brushing technique results in a long stroke pattern. To some satin is the same as a brushed finish. The 2b mill finish is achieved with an additional light cold roll pass and is the standard finish for 201 301 304 304l and 316l stainless steel.

Satin finishes can be obtained with metal brushing or they can be scratched with sandpaper or other abrasive material rather than with a metal brush. The resulting stainless steel finish is capable of reflecting clear images. Commonly for stainless steel it is less glossy than a polished surface with a unidirectional linear grained brushed finish having transverse ra of about 0 5 microns. To others it means a translucent frosted milky look.

Stainless steel with a 2b finish is generally used for bakeware and flatware plumbing fixtures solar panels industrial equipment and wheel covers. It is very smooth and less likely to harbour airborne contaminants and moisture compared to any other mill finishes.